The Art of Illusion: Creating a Basket Weave Box with Hot Sand Shading

In the world of fine boxmaking, it’s often the most minor touches that leave the strongest impression. Sometimes it’s the smoothness of a finish, the way a grain wraps around a corner, or — in this case — how light and shadow can trick the eye into seeing depth on a flat surface.

One of the most fascinating techniques in traditional marquetry and veneering is hot sand shading — a method that, when executed with precision, creates a beautiful three-dimensional illusion on a two-dimensional surface. It’s a technique that requires patience, a steady hand, and a good deal of heat.

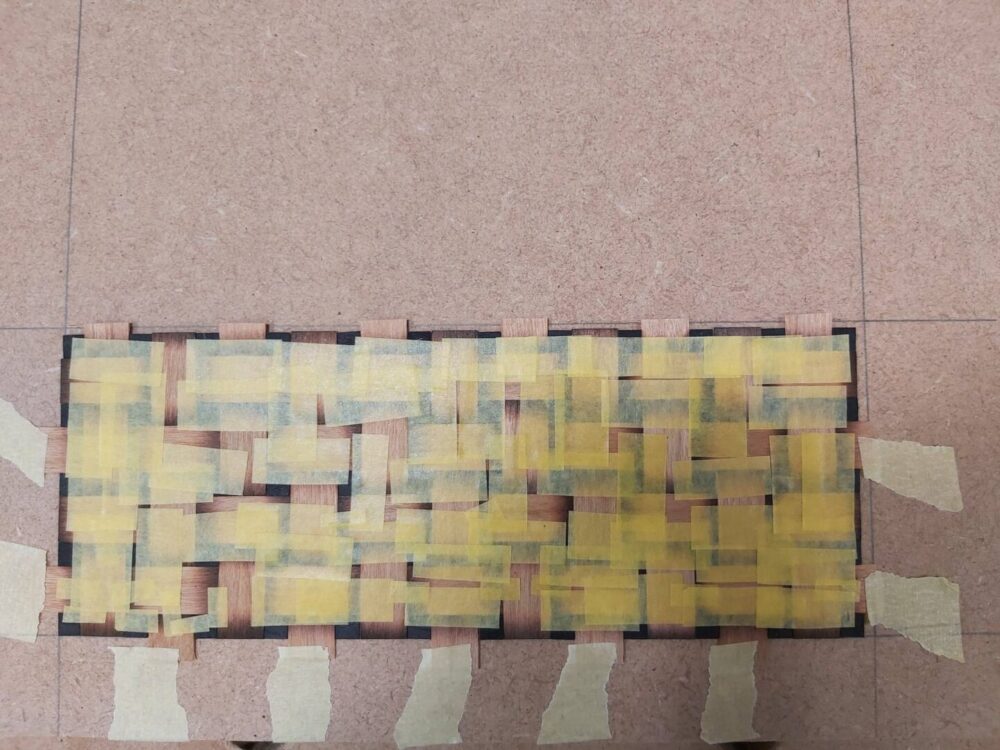

For one particular project — a bespoke basket-weave box — I had the opportunity to revisit this traditional approach and apply it in a contemporary way. The result was a box that blended classic craftsmanship with a striking, almost optical design.

What is Hot Sand Shading?

Hot sand shading is a time-honoured technique used in fine woodworking and marquetry to give flat pieces of veneer the illusion of depth. By lightly scorching the edges of selected pieces in heated sand, the wood darkens at the contact points, creating a subtle shadow effect.

When these shaded pieces are assembled in a particular pattern, such as a weave, the effect can be startlingly three-dimensional. It’s the kind of technique that invites a second look: at first glance, it appears as a raised or textured surface, but it’s entirely flat to the touch.

Building the Illusion, One Piece at a Time

The basket-weave pattern was explicitly chosen to showcase the hot sand shading technique. To achieve it, I began by selecting high-quality veneer with a consistent grain and tone. Each small strip was cut to size, and the edges individually scorched in heated sand. Timing is everything, too little and the effect is lost, too much and the piece becomes brittle or overly charred.

Once each piece was shaded, they were carefully laid out and joined together by hand to form the weave pattern. This part of the process is like solving a jigsaw puzzle, but with wood, every joint must be precise, every line straight, every shadow consistent.

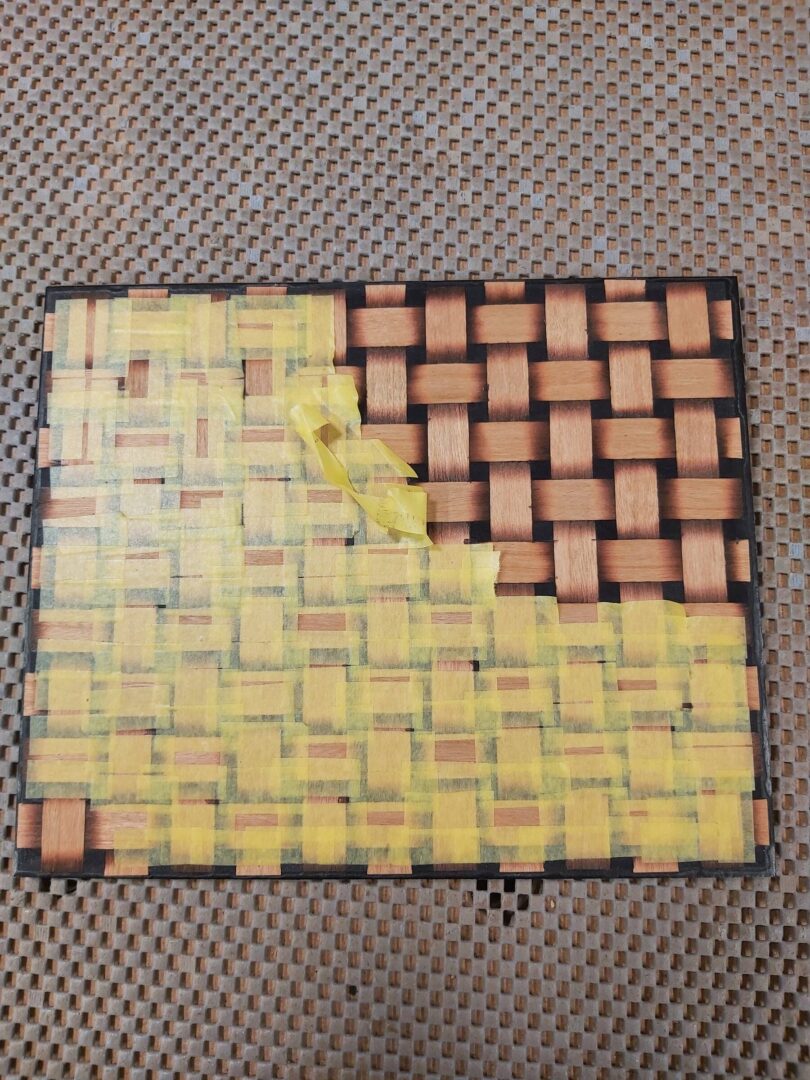

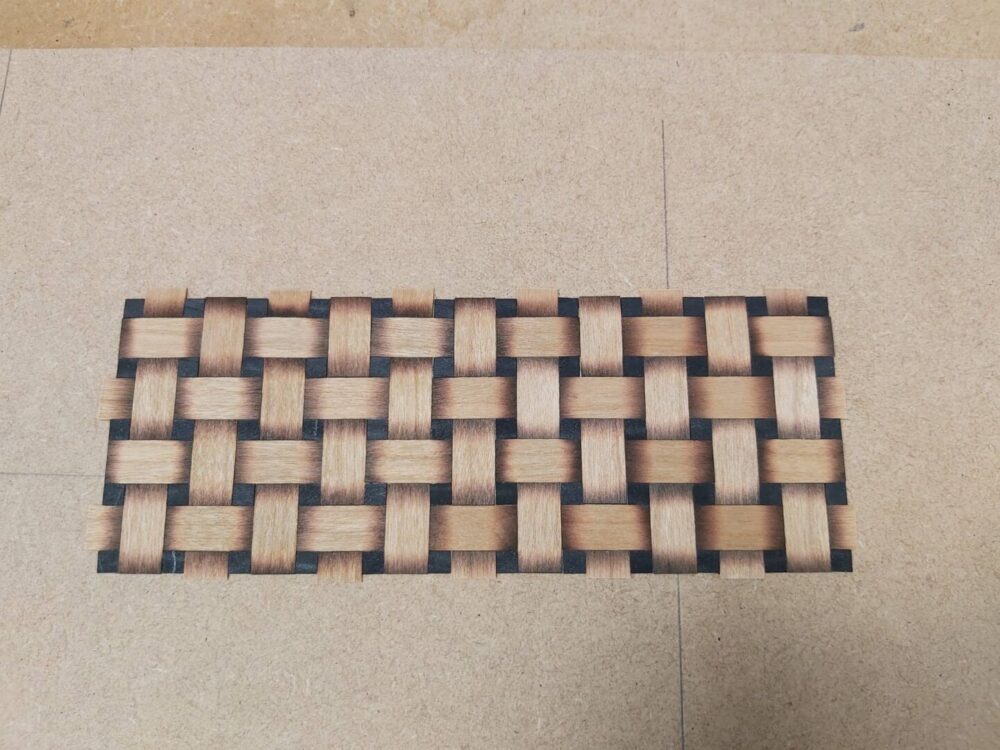

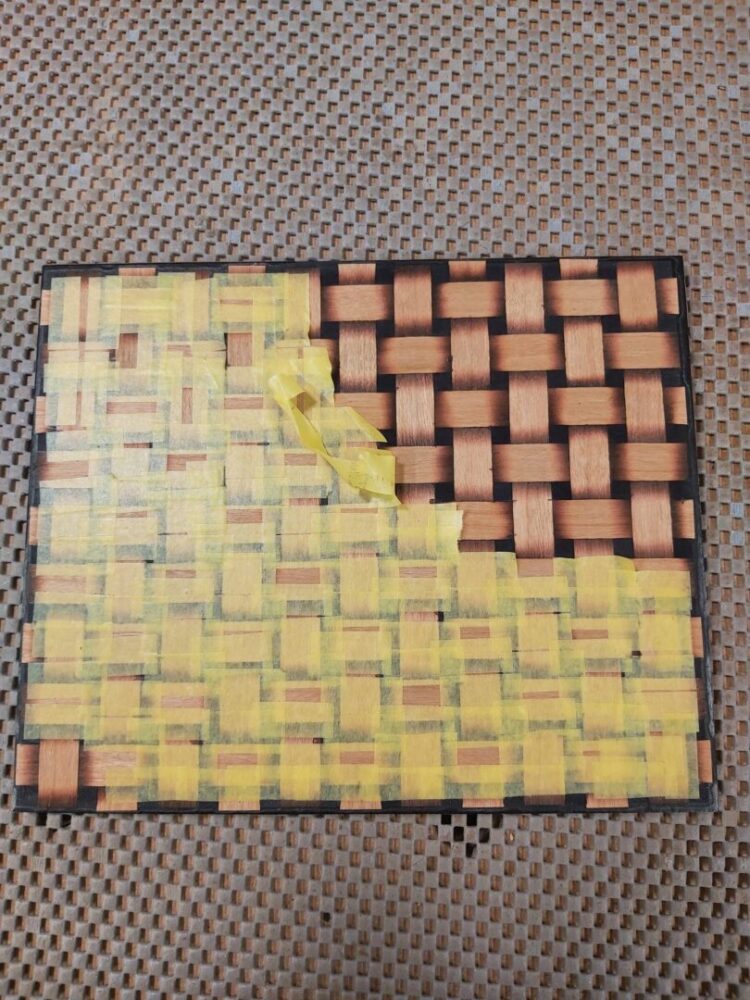

When complete, the full sheet of basket weave marquetry was pressed onto the substrate — the base surface that would eventually form the sides of the box. The glueing process must be done evenly and with great care to avoid any warping or misalignment in the final pattern.

Shaping the Panels and Forming the Box

With the veneer sheet in place, the next step was to cut the panels for the box. This is where everything must stay perfectly square and aligned — any mistake in measurement or angle will disrupt the visual rhythm of the weave pattern.

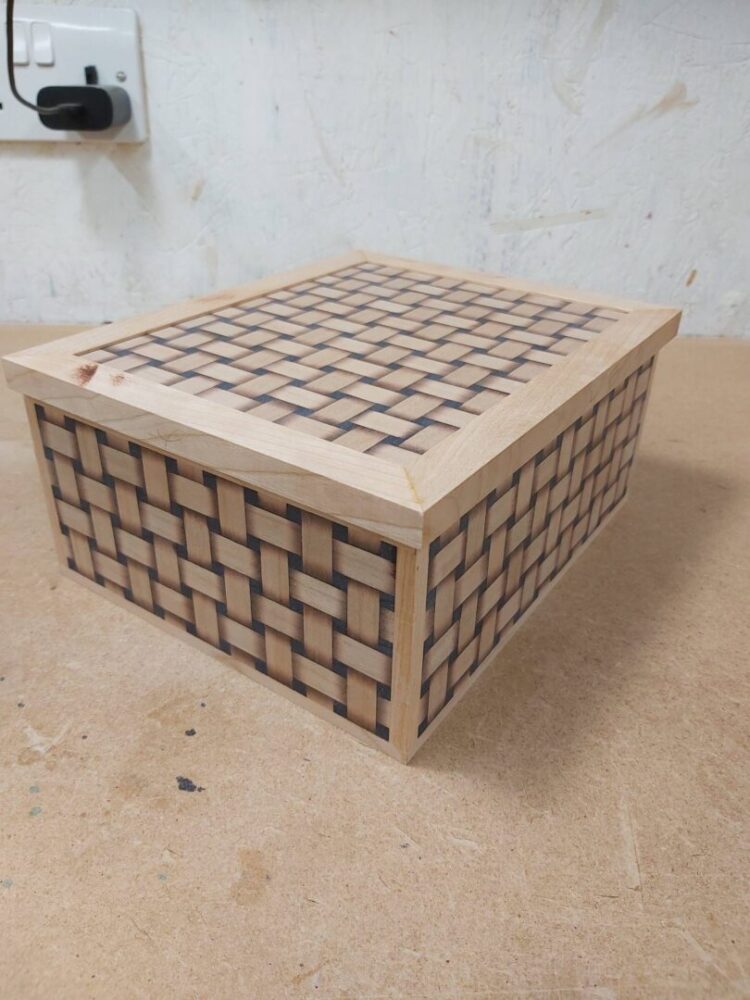

Each panel was then joined together to form the box body. As always, attention to grain direction, joint strength, and corner alignment was key. Once assembled, the entire box underwent a meticulous sanding process to bring out the natural sheen of the veneer and ensure every surface was flawless to the touch.

A Unique Result from a Classic Technique

The final result is a box that immediately captures attention. The weave appears to rise and fall across the surface, even though it’s completely smooth. It’s a testament to how traditional techniques, when applied with care and a bit of creative flair, can produce something truly unique.

Hot sand shading might not be used often in modern furniture making, but it remains a favourite among those who appreciate the artistry behind the craft. This project was an opportunity to celebrate that tradition and offer something that looks as interesting as it is to create.

Every box has its story. This one is a story of shadows, light, and illusion — and a reminder that sometimes the oldest tricks in the book are still the most effective.